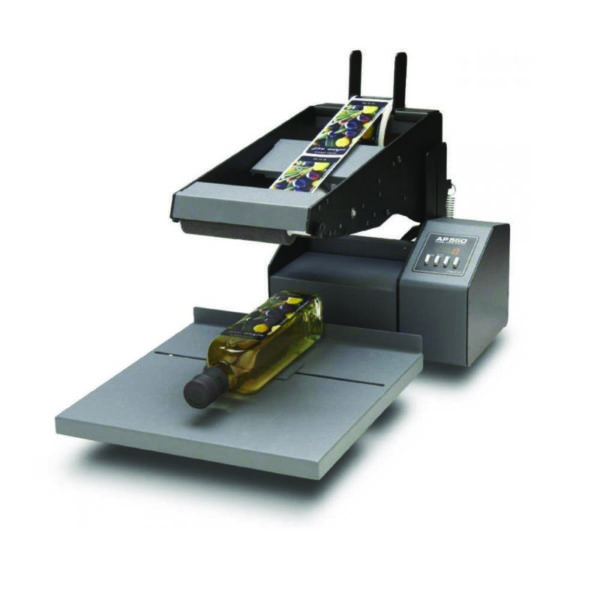

Primera's label applicators are the perfect semi-automatic label solution for cylindrical containers as well as conical containers such as bottles, cans, jam jars and tubes.

The new version at Karley - AP360e with *3 years warranty after registration with the manufacturer after purchase within 6 months!

The setting as well as the operation is very easy:

-

- Set the guides

- Place your container in the machine

- Press the foot switch and the label is applied.

- Call customer support if you have questions

The AP360e's built-in print arm ensures that labels are applied firmly and without angles (corners).

With the label applicator of the AP series, you will be able to work faster and more accurately. With higher operating speeds, you can produce and sell more products.

Apply labels quickly and accurately with an AP label applicator, achieving speeds of up to 1200 labels per hour in laboratory tests. The labels are applied without wrinkles, giving your product a professional appearance.

The AP series label applicators are an ideal complement to Primera LX or CX label printers. Of course, you can also use them without a Primera printer with most OFFSET labels or other pre-printed labels.

There are 2 models

AP360e is the basic model. It quickly and effectively applies individual labels to your containers.

AP362e is the larger model with more capabilities. It can apply one or two different labels to a container at the same time. A built-in LED counter and memory for up to nine label presets are included.

If you have flat containers, Primera now offers the AP550e label applicator.

Features:

-

- Simple setup and operation

- The AP360e ensures accurate label application on the front side

The AP362e model allows for accurate label application on both the front and back sides with variable spacing - Fast - labels can be applied at approx. (135 mm) per second, which means up to 1200 containers per hour depending on the label

- Compact dimensions - fits on almost any table

- Professional design - one of the only semi-automatic label applicators with UL, CSA, and FCC safety and emissions certifications!

- Built for industrial application - extra heavy-duty construction for durability.

Suitable for:

- Bottles (label / labels on bottles)

- Cans (spices, drinks...)

- Jars (jams, sweets...)

- Tubes (silicone, glue...)

- Attach labels

How many labels can the Primera AP360e apply per hour?

„Fast production: 135 mm/s – that's equivalent to labeling up to 1200 containers per hour," says the datasheet, and of course, this also depends significantly on the size of the containers and labels. But the 135 mm/s is fixed, and what this means for normal 0.5 L drinking bottles has now been published by Primera in a short video! You can watch the video as the last one in the gallery above this description.

Important note

The flexibility or stiffness of the label also plays a role. If the label is too flexible, regardless of its thickness, it may cause wrinkles or may not separate from the carrier when reaching the peel edge. Polypropylene, polyester, and vinyl labels tend to be more flexible than paper labels. If you're not sure if the label is too flexible, we recommend testing it beforehand before deciding on purchasing a label material or label applicator.

Key data to consider:

Strength of the face material and adhesive: 127 µ – 381 µ

Thickness of the backing material: 50,8 µ – 254 µ (Glätte des Materials beeinflusst die Zuführung – Ein zu glatter oder zu dünner Träger kann durch die Antriebsrollen rutschen)

Thickness of the label material: 5 mil – 15 mil

Container width: 25.4 mm to 238 mm (length or max. height of e.g. bottles)

Your material can be wrapped outside or inside - the important thing is the thickness! Have it tested free of charge at Karley!

We test for you whether the AP360e is suitable for your products - via video conference

At Karley, we have tested thousands of products with Primera applicators for our customers. You send us your products as they should be labeled, along with a roll of leftover labels. If you use our label material, we don't need labels from you, just the label size and material information. Our technicians then take your products, place them in the applicators, and create a small video for you. Alternatively, we can arrange a brief video conference with you so you can see live how your products are being tested. This ensures that this combination is suitable for you, and our experienced technicians may also identify potential issues and solutions. However, please contact us first with a picture, dimensions, and weights of your labels. Since we have tested many products, we can often provide information without conducting this test.

Monika A. Franke –

Ich bin ich sehr zufrieden mit dem AP360e Etiketten Applikator. Es hat mir viel Zeit und Mühe gespart und meine Produktivität gesteigert, denn es war davor echt viel Arbeit, die Etiketten alle per Hand anzubringen. Der Applikator ist robust und hat eine gute Qualität. Ich würde es auf jeden Fall jedem empfehlen, der regelmäßig Etiketten aufträgt. Für ein kleines Unternehmen sehr gut geeignet.

Nicht verifizierter Kauf. More information

J. Meyer –

Das Basis Modell ist für mich persönlich vollkommen ausreichend. Für jeden, der viele Etiketten anbringen muss, super geeignet. Ein echter Work-Changer! Die Etiketten werden schnell und ziemlich genau angebracht.

Nicht verifizierter Kauf. More information